Humans have always depended on technology to improve our quality of life. The advancements of industrial robots continue to multiply. Precision manufacturing remains constant in improving Computer Numerical Control (CNC) machining. The CNC machine is a groundbreaking piece of industrial robots that have made production more accessible, faster, and overall better in every aspect of manufacturing.

Computer Numerical Control

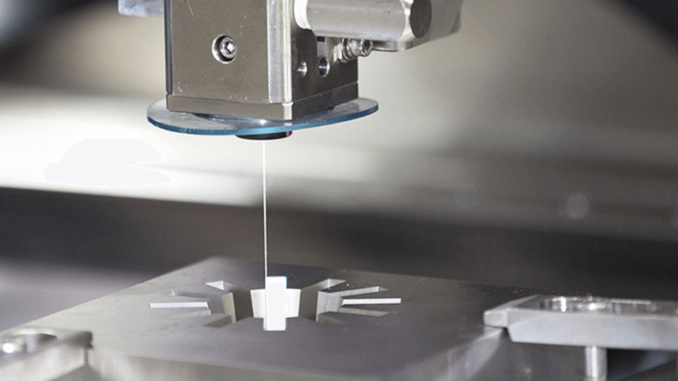

A CNC machine is a machine that uses specific code from a program to cut into raw material producing a product. A basic approach to understanding the device is that a person wishes to create a model home. First, a model design is put into a computer software program, like CAD. The CNC machine interprets the code. The person then places raw material on the machine, such as plywood.

Then, the machine cuts various shapes out of the plywood. Those shapes are then taken to create the model home. Now, imagine creating objects meant to build jet engines. CNC machines have the precision to make anything.

Types of CNC Machines

There are various types of CNC machines and programs that accompany the robot. Here are a few different kinds of devices and their benefits:

- CNC Lathe – Although this machine has fewer axes to choose from, they are still highly accurate. The primary function of the CNC lathe is to cut material as it rotates.

- CNC Router – Uses CNC control to cut its paths. One of the most significant advantages to the router is its minimal waste since it uses as much as the material necessary.

- CNC Laser – One of the few machines that use a laser to cut raw material. There is no need to replace a drill or blade and cut through metals and plastics.

Axes and CNC Machines

The functions of axes are essential depending on what you expect out of your CNC machine. There are 5-axis points to take into account when choosing. 5 Axis CNC Machining provides full axis function compared to 2, 3, or 4 axes. The 5 axis machining offers greater accuracy and freedom to cut. The process is easy to set up and has minimal collision compared to the other axis points. A 5 Axis CNC machining is an excellent option for plenty of freedom compared to other axis points.

Try it Out

There are many CNC machines and axis points to choose from. Before buying a machine, be sure to conduct plenty of research. Get a device that fits the company’s goals and objectives. Also, be sure to have the best people on the job to perform with the machine. CNC machines continue to improve and will stay established in precision manufacturing. Make sure you continue to grow with it.

Leave a Reply

You must be logged in to post a comment.